We operate the latest fruit packing technology and are continually refining our processes to ensure we produce the highest quality fruit.

Our coolstores are powered by natural refrigerants with the latest temperature, humidity, and atmospheric controlling technology ensuring that K-Fruit remains at its best.

Outside of our peak season, third parties can utilize our coolstore facilities and be confident they are being environmentally responsible and operating efficient technology.

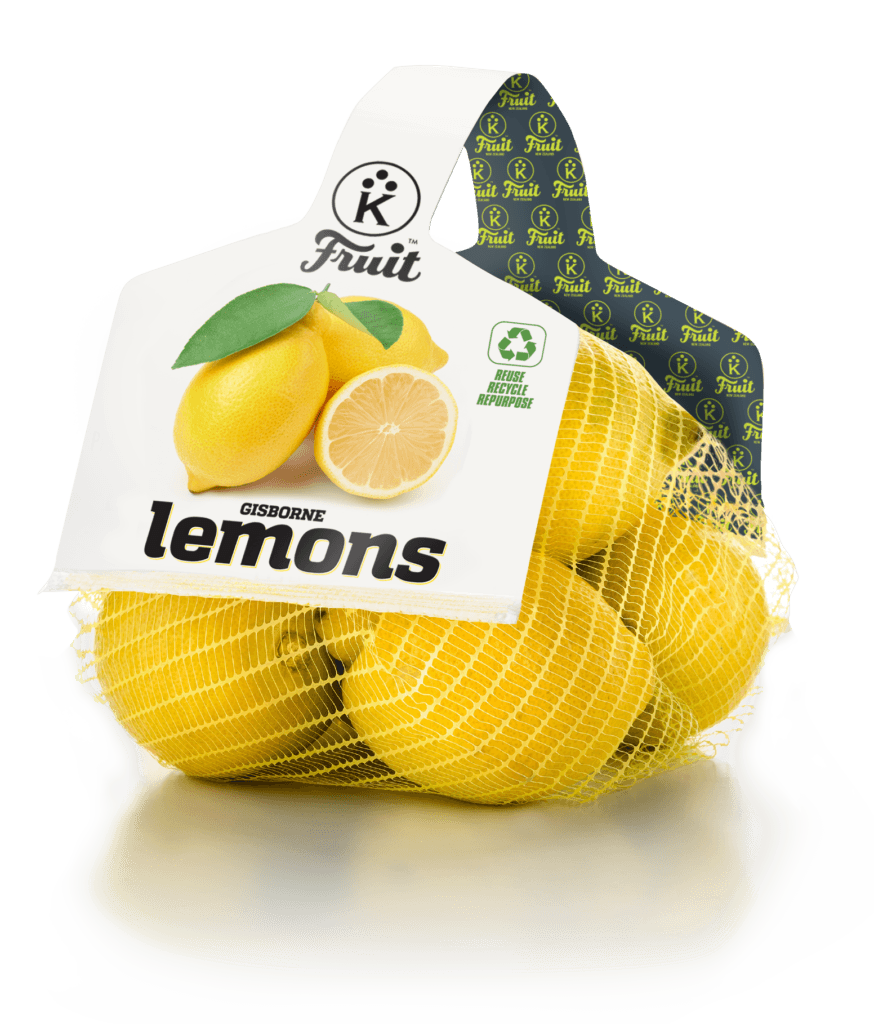

We pack fruit into a wide range of packaging formats to meet the needs of our customers. This includes recyclable cardboard boxes, reusable crates, and compostable pre-pack bags.

Kaiaponi Farms is only ten minutes from the centre of Gisborne where we have world-class surf breaks, bars and restaurants and a world-famous music festival.

We provide excellent working conditions and on-site seasonal accommodation.

Search

Get in Touch